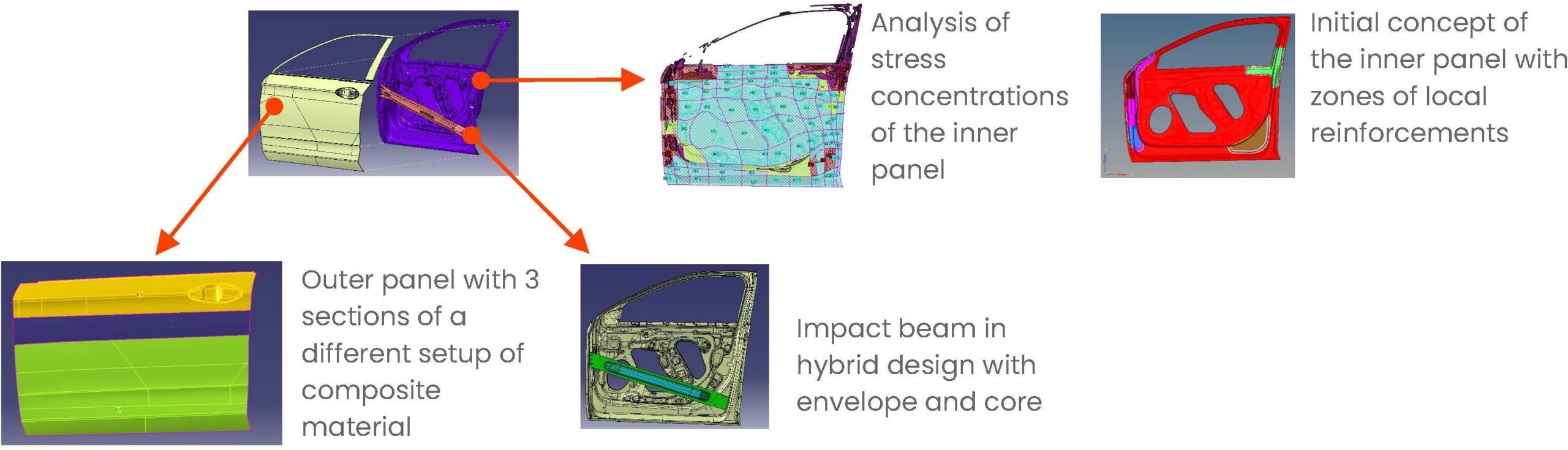

Car door in lightweight design

A car manufacturer commissioned a study to determine whether the weight of its car doors could be significantly reduced. The task was to convert the conventional door to a lightweight design, taking into account structural constraints and, in particular, crash absorption capacity and costs.

To this end, the various components that perform the sub-functions were considered separately. Various new concepts were then designed for each of these, enabling them to fulfill their function with reduced weight.

These were then also considered separately, but taking into account their constraints, analyzed and evaluated in terms of the specifications to be met. Concepts that proved to be less suitable were rejected. Further adjustments were then made to the remaining concepts in order to approach the targets and ultimately meet them.

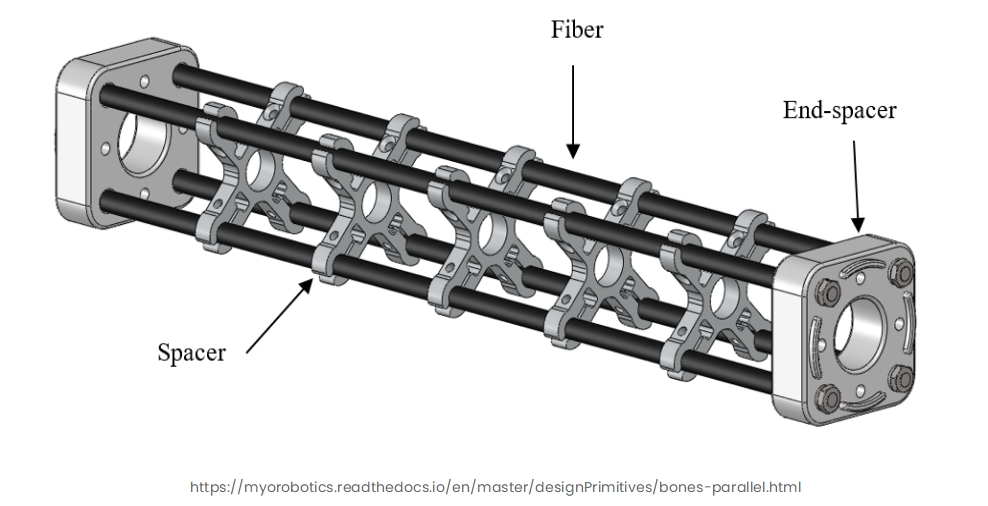

Lightweight robot arm

Lightweight design is essential for robots, as they have to manage their energy, which is often supplied by batteries, extremely efficiently. More mass leads to significantly higher energy consumption.

A thorough investigation of the existing load and movement scenarios is required here first. For an arm structure based on the human arm, a solution was ultimately chosen in which four carbon fiber composite tubes were connected on the outside with five retaining spacers arranged in a row. Circular recesses inside the spacers are used to direct electrical cables.

Li-Ion test batteries

In just a few years, Li-ion batteries have become a crucial component for many applications, serving as energy storage devices.

However, testing real Li-ion batteries involves significant risks, particularly the danger of explosion. It therefore makes sense to remove the electrochemical composition and simply simulate its effects.

For the development of these test batteries, the housing and connection dimensions were adopted 1:1 and a mechanism was then incorporated to simulate the flow of current and heat generation. These test batteries were then used in various test benches, including one that transmits vibration loads.

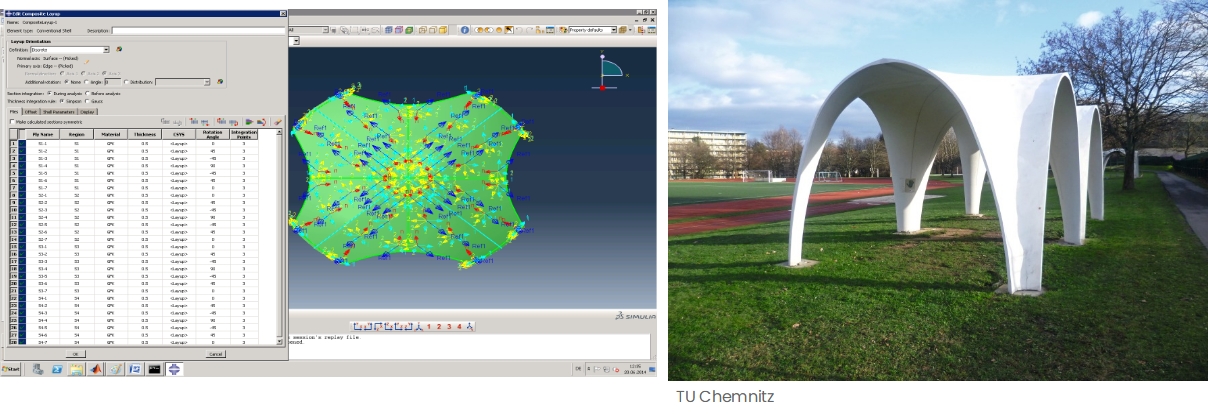

Pavillon GFRP & fiber concrete

It can be said that one of the earliest applications of lightweight design was established in the building industry. It is said that in ancient Egypt, straw was mixed into clay (i.e. a composite material) because it was recognized at the time that this had better properties than clay alone. Today, the construction industry is considered very conservative and generally uses solid construction methods.

Lightweight design technologies are currently experiencing a revival in the construction industry, as their use can open up significantly greater design freedom. This in turn enables architects and designers to realize new, aesthetic forms.

In this case, the project involved a pavilion made of a hybrid material. This consisted of GFRP (glass fibre reinforced plastic) on the one hand and fibre-reinforced concrete on the other, which were bonded together.

The finite element method (FEM) was used to investigate how typical environmental loads affected the pavilion with its special configuration. This included considering a long-term snow load and the stresses resulting from heat and cold. Since the different materials behave differently in response to temperature changes, stresses arose in the adhesive bond that therefore deserved special attention.